High-Speed Data for Large-Scale Solutions

Mike Wolfinger, Director of Engineering at FUJIFILM Integrated Inkjet Solutions, discusses advances in variable data imprinting technology

Variable data printing and inkjet imprinting bars have been available on the market for many years and technology is constantly being developed. However, it is important to be aware that speed and resolution are provided at differing degrees. In addition, these variable data capabilities exist on a spectrum.

Traditional limitations

Speed, resolution and variable data handling capabilities are often in direct conflict with each other. According to Pat McGrew at McGrewGroup Inc., traditional variable data imprinting, for applications such as putting addresses on mail, was designed to print individually unique information inline on analog presses operating at an estimated 500–1,000ft/min. As a result, the variety of image types – such as fonts and artwork – as well as print resolution can be limited.

Download a PDF copy of this article as it appeared in Specialist Printing Worldwide.

Fujifilm print speed

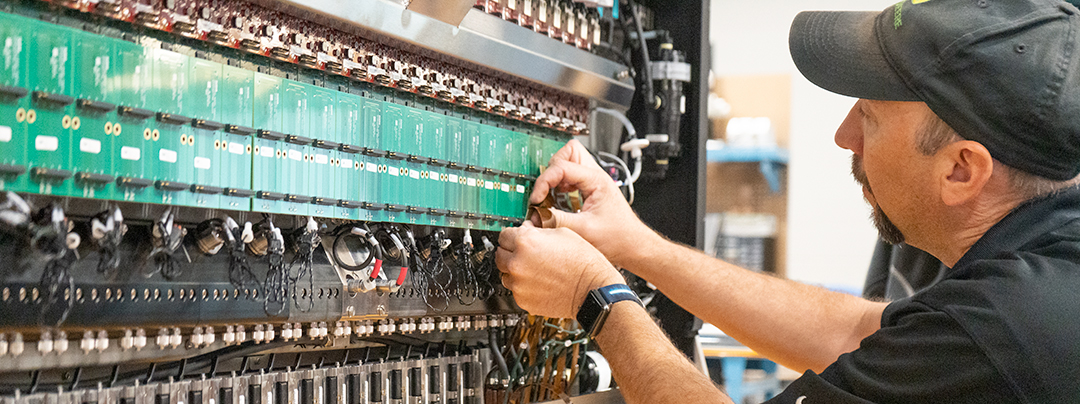

The FUJIFILM SAMBA printhead, which first came onto the market in 2013, opened new possibilities for print system developers. It has a native resolution of 1,200 dpi and packs 2,048 nozzles into a width of only about 1.6 inches. This nozzle density can be leveraged for impressive image detail, resilience via nozzle redundancy and fast print speed. However, without a system architecture capable of maximizing the potential of such a printhead technology, the result can be a system design based on major performance trade-offs where only variable data capability, print speed or image quality (but not all three) are able to be maximized.

Nozzle numbers

What does it take to effect this in a print system? It is important to understand the number of nozzles in the system.

Let’s consider a real-world example where we have six 27-inch webs, each printing duplex. That equates to 12 printbars, each with 16 FUJIFILM SAMBA printheads. That’s 192 printheads, each with 2,048 nozzles, resulting in 393,216 nozzles requiring jetting commands. To print at over 1,000ft/min, the nozzles need jetting commands at a rate of 60kHz – 60,000/sec. Directing 393,216 nozzles at this rate equates to over 24 billion jetting commands processed and transferred per second!

Directing 393,216 nozzles at this rate equates to over 24 billion jetting commands processed and transferred per second.

Comparison to MBPS

Another way to look at it is that 24 billion jetting commands per second is equal to 24 gigabits (Gbps) per second. Home internet speeds of one Gbps are growing in popularity and availability. In this setting, 24 Gbps in a professional production setting, might not sound all that impressive. However, it is important to note that internet providers typically quote their maximum speed, but customers don’t usually experience this best-case scenario when using the service. For example, at the time of writing (in December, 2022), I tested my home office ‘one gigabit, high-speed internet’ service using one of the various public, on-line internet speed test tools and discovered that it was running at only 830 Mbps/sec.

As another point of reference, video streaming in today’s 4K format runs at about 32 Mbps/sec, which is exponentially less than one Gbps. So, if the 12, 27-inch print bars were showing movies instead of printing, you would be able to watch 750 movies (24,000/32) in your house at the same time. However, when video streaming outpaces the internet speed, annoying pauses and sometimes a drop in picture quality occurs. Such effects would be disastrous for inline inkjet printing because that would mean the printer determines the net production speed of the factory. In this scenario, the speed and its reliability are important.

The data processed by twelve of our 27-inch printbars is equivalent to watching 750 movies in 4K at the same time.

Ensuring speed reliability

Every time data is read from, or written to, a hard drive, potential latency is introduced which can slow the data speed. Fujifilm has developed a data-processing architecture that avoids the use of hard drives. Instead, Fujifilm uses a complex system of modular, overclocked computer processors and RAM to provide lightning-fast speeds over a wide range of potential data demands.

This modular data-processing architecture has led to a high-speed, 1,200dpi print system which can process unique images on each page. There are virtually no restrictions on the type of imagery that can be sent to this print system. In addition, Fujifilm has ensured that the system is not limited to this one configuration as in inkjet integration, configuration needs are endless. The next customer may want 12, 13-inch print bars, or 10, simplex, 10-inch print bars. If the number of printheads changes in a configuration, the number of nozzles changes as well. The number of nozzles then affects the amount of data needed. As the data needs increase or decrease, the cost of the system must scale in a reasonable way without compromising resolution, print speed or variable data capabilities.

Conclusion

FUJIFILM Integrated Inkjet Solutions has found a scalable way to offer 1,200 dpi, high-speed, variable data printing. Users who have witnessed the FUJIFILM SAMBA print systems in action have been impressed by its ability to eradicate sacrifices and meet all variable data printing requirements.